THE CHOICE

OF LIVESTOCK

PROFESSIONALS

Projects

Yocham Ranch

Texas, USA

“The whole process couldn’t have been smoother, and we’re very happy with the quality of the product.

If you’re thinking about new facilities, I absolutely recommend ProWay to anybody looking to build something like we’ve got. It’s awesome, it really is.”

BONNIE DOON WAGYU

Nsw, Australia

“I can’t fault ProWay, from the design process to the finished product it’s been excellent really. I would definitely recommend them. You know what you’re going to get. It’s a quality product that works well and will last.”

'west diggora'

diggora west, VIC

“You use the Bulkie for more things than you thought you might, by the end of the day you turn over your shoulder and they’re all done!”

Built for professional livestock producers & processors

Rob Wilson

Bonnie Doon Wagyu | Morven, NSW

“We wanted the new design to feature ease of stock flow and management. Since the ProWay yards have been put in, everything flows evenly. I like the design, I like the materials, and they’re are a very good company to work with”

Tom Wilson

Salt Creek Merinos | Woorndoo, VIC

“The Bulkie just takes all the stress out of the job for livestock and operator. You knock off feeling great, and every animal gets an accurate treatment”

Andrew Carmichael

Patanga Park | Buffalo, VIC

“If you look at the overall expense they are an asset that is going to last at least forty or fifty years. They’ll see me out and they’ll be more than likely to see my son out. Over that period of time a fairly cheap investment”

Griff Symonds

Mt Flora Station | Nebo, QLD

“Working in these yards, there’s a lot less stress on the operator and a lot less stress on the animals. Having a set of yards that we can just walk straight in to knowing they’re ready to go is so important. We’re not worried about maintenance or repairs and we know we can rely on them”

Frank Archer

Landfall Angus | Tamar Valley, TAS

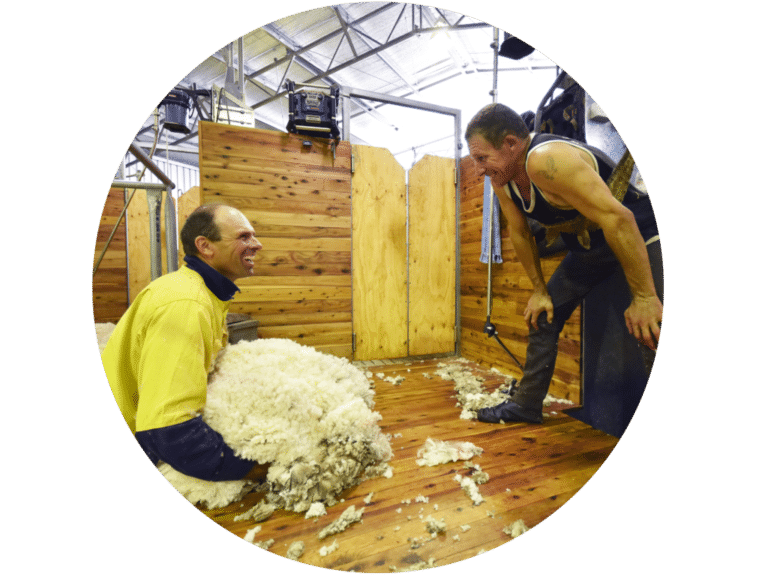

Tom Ellis

Coola Station | Mt Gambier, SA

“I’m very impressed with the sawtooth arrangement. It is much easier for the shearers. Dragging straight out of the pen means that they don’t have to turn another 90 degrees…

Apart from the shearers, everyone is upright the entire working day. After working on a flat floor, the raised board is an absolute joy”

Rupert McLaren

Glenmore | Barmedman, NSW